Introduction to Belt Presses in Wastewater Treatment

Modern wastewater treatment involves complex processes for handling and disposing of sludge. Among the most pivotal tools facilitating this operation are belt filter presses. These machines efficiently dewater sludge, converting large volumes of liquid waste into compact, manageable solids. By shrinking the overall waste stream, facilities save both time and resources on transport, storage, and disposal.

Most importantly, belt presses are engineered for consistent performance, making them an excellent choice for facilities that require continuous sludge management. For organizations seeking adaptable, on-demand solutions, belt press rentals offer a practical solution, enabling rapid deployment and short-term scaling to meet varying processing demands. With minimal setup requirements, these rentals can quickly integrate into existing operations, reducing downtime. Additionally, they provide an economical alternative to purchasing new equipment, particularly for seasonal or temporary processing needs.

How Belt Filter Presses Operate

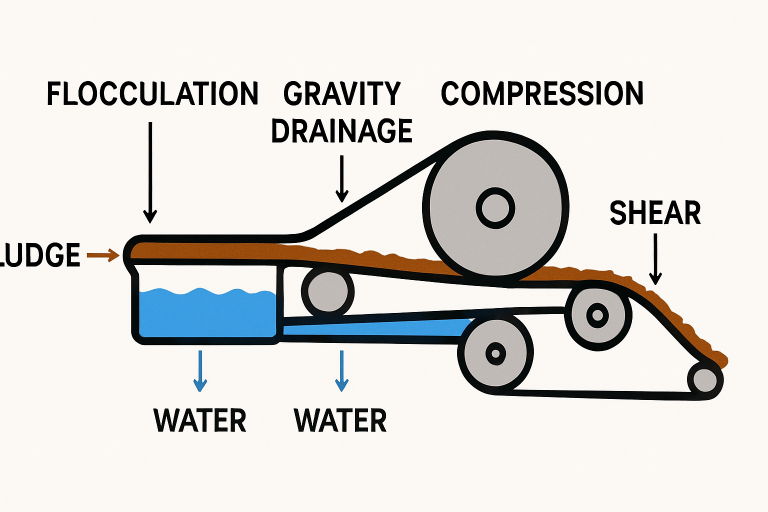

Belt filter presses work by systematically applying mechanical pressure to sludge held between two porous belts, a process the EPA describes in detail on its fact sheet, efficiently reducing water content and producing manageable solids. The process consists of four main stages:

- Flocculation: The addition of chemicals causes fine sludge particles to clump together for easier separation.

- Gravity Drainage: The mixture is slowly passed over a moving porous belt, allowing free water to drain by gravity.

- Compression: The partially dewatered sludge is compressed between two belts, forcing additional water out through the filter media.

- Shear: The remaining solid cake is gently scraped away as the belts separate, leaving a much drier product for disposal or incineration.

This staged approach maximizes water extraction, reduces handling difficulties, and produces a final product that requires less costly landfill space or further treatment.

Advantages of Using Belt Presses

Facilities opting for belt filter presses gain several key operational and financial advantages:

- Continuous Operation: Belt presses can run around the clock, supporting the consistent inflow and handling requirements of larger treatment plants.

- Energy Efficiency: These systems generally use far less energy than alternatives such as centrifuges or vacuum filters, resulting in ongoing cost savings and a reduced carbon footprint.

- Reduced Sludge Volume: By producing a drier, denser cake, facilities significantly lower disposal costs and truck trips, which has both fiscal and environmental benefits.

Environmental Impact and Sustainability

Belt filter presses directly contribute to sustainable wastewater management. The primary environmental benefit is reduced waste sent to landfills, significantly lowering overall transportation requirements and associated greenhouse gas emissions. Additionally, belt presses are recognized for their energy-efficient operation—using notably less power than alternative dewatering systems. This efficiency aligns closely with broader sustainability objectives in modern municipal and industrial water treatment.

Recent Technological Advancements

Innovations in belt press technology have delivered significant industry benefits:

- Enhanced Odor Control: New models feature integrated odor containment enclosures, substantially improving the surrounding environment for operators and nearby communities.

- Increased Cake Solids: Advances in belt material and design now enable higher final solids concentrations, improving dewatering outcomes and resulting in even greater reductions in disposal volumes.

- Reduced Maintenance: Upgraded bearings, self-cleaning mechanisms, and more intelligent monitoring systems lower maintenance demands and minimize downtime—key for non-stop plant operations.

Considerations for Implementation

Successfully introducing a belt filter press system requires careful planning. Facilities must evaluate:

- Sludge Characteristics: Composition, volume, and expected variability must be assessed to ensure optimal press sizing and chemical dosing.

- Operational Costs: Analyzing lifecycle expenses, including energy consumption, reagent use, and ongoing maintenance, helps decision-makers forecast long-term value accurately.

- Space Requirements: Belt presses require specific layout accommodations, so facilities must verify available space for both installation and routine operation.

Conclusion

Belt filter presses stand out as essential assets for modern wastewater treatment facilities seeking to manage sludge efficiently and cost-effectively. Their many operational and environmental benefits continue to expand with each new generation of press technology. Through strategic planning, ongoing investment in technology, and a focus on sustainability, these systems will remain cornerstones of the wastewater treatment process for years to come.